Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

How PC achieves excellent mechanical performance (tensile, flexural, impact)?

Factors affecting PC's impact resistance:

1. Molecular Weight: Higher molecular weight improves impact resistance.

2. Molecular Weight Distribution: Narrow distribution enhances impact resistance.

3. Processing Conditions: Parameters like temperature affect molecular arrangement.

4. Additives: Impact modifiers, e.g., elastomers, boost impact resistance.

5. Temperature: Extreme temperatures may reduce impact resistance.

6. Notch Sensitivity: Notches or defects can decrease impact resistance.

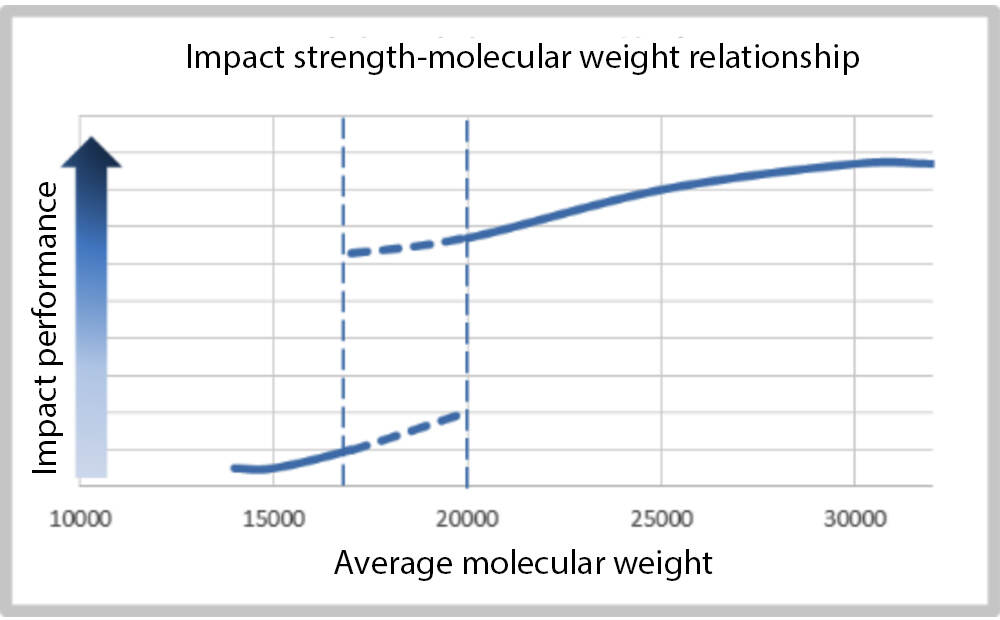

Molecular weight:

In a certain range of molecular weights, polycarbonate exhibits better impact resistance with higher molecular weight. However, simply increasing molecular weight doesn't guarantee stronger impact resistance. There exists an optimal molecular weight range where impact resistance peaks, beyond which it may plateau or decline.

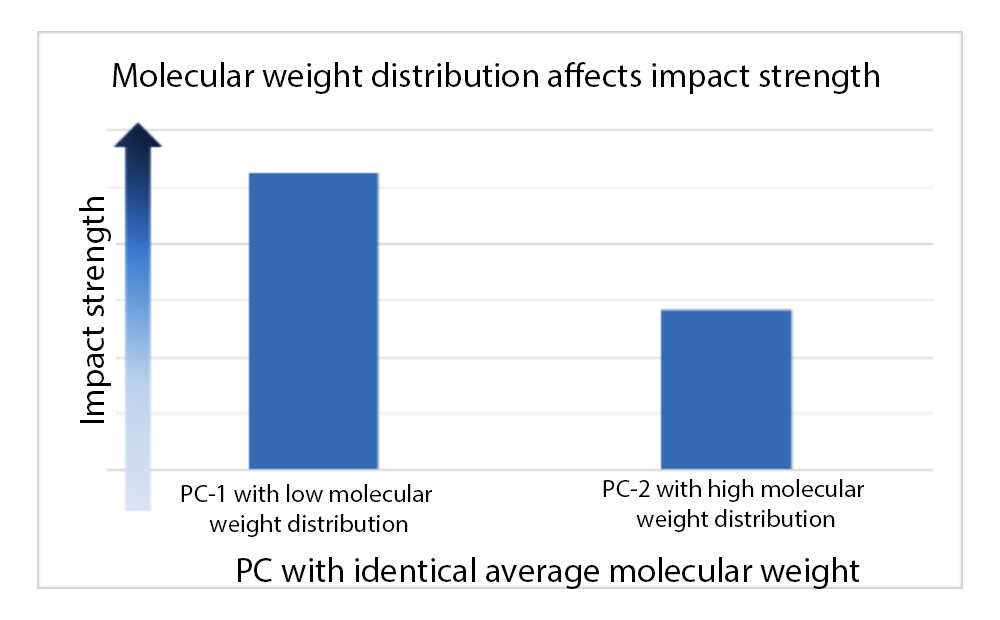

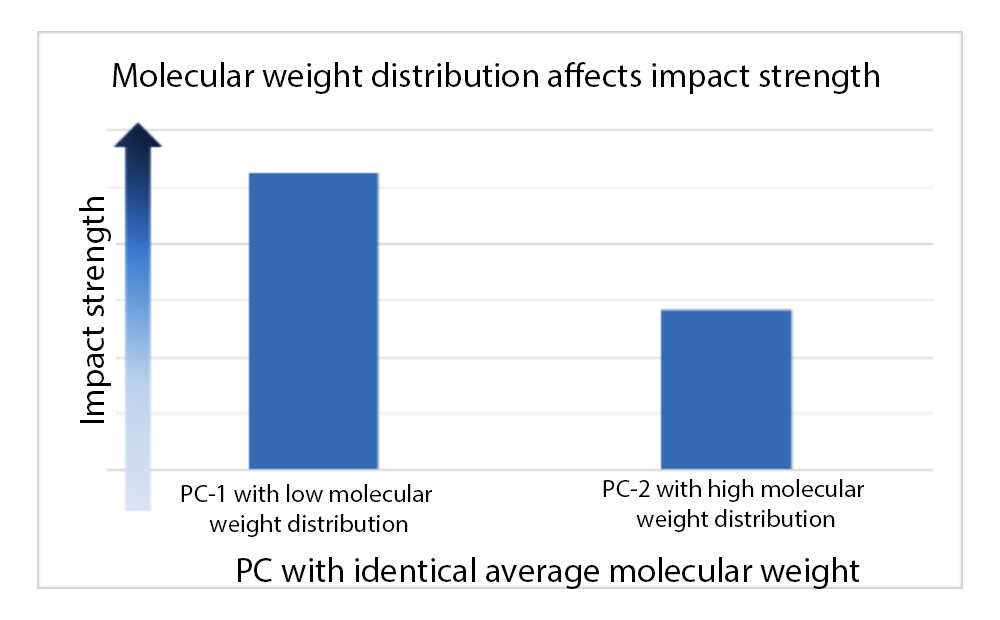

Molecular weight distribution:

Molecular weight distribution affects polymer properties. Lower molecular weight fractions weaken polymer strength, impacting polycarbonate's impact resistance.

Post-processing techniques:

Post-synthesis treatments can lead to a decrease in molecular weight of polycarbonate. Effective post-processing techniques can help maintain its excellent impact resistance. The impact strength is not significantly affected by the synthesis method but is more influenced by the differences in synthesis and post-processing techniques.

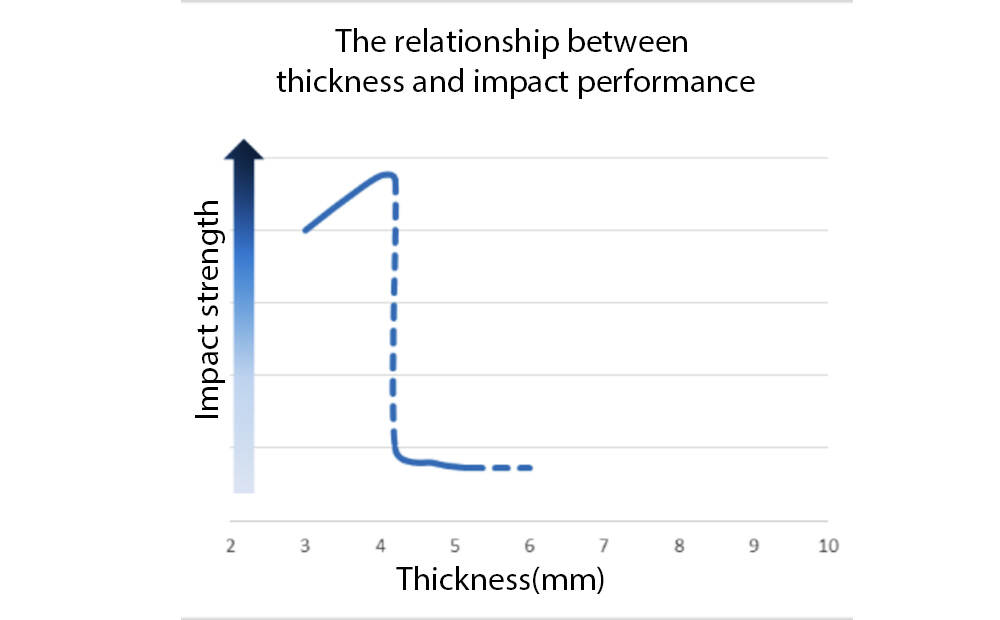

Material thickness:

Material thickness is a critical factor to consider in the testing and molding of polycarbonate. Once the thickness exceeds a certain value, the material's impact resistance significantly decreases due to a transition to brittle fracture. Therefore, only the appropriate thickness can showcase polycarbonate's excellent impact resistance.

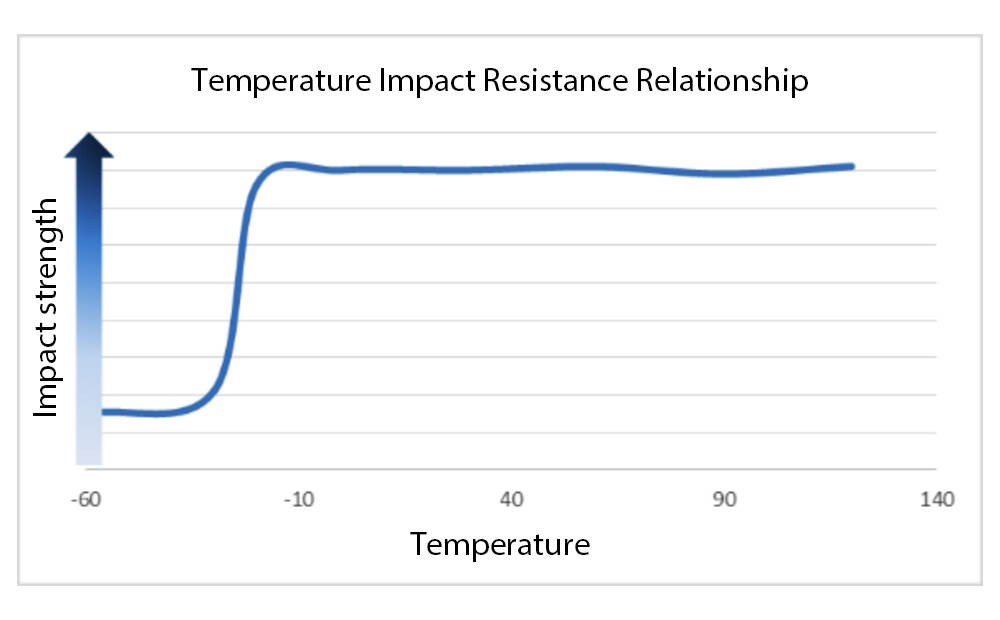

The effect of test temperature:

Within a specific temperature range, polycarbonate's impact resistance decreases with decreasing temperature due to a transition from toughness to brittleness.

In addition to the aforementioned factors, the type of additives also influences the impact resistance of PC.