Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

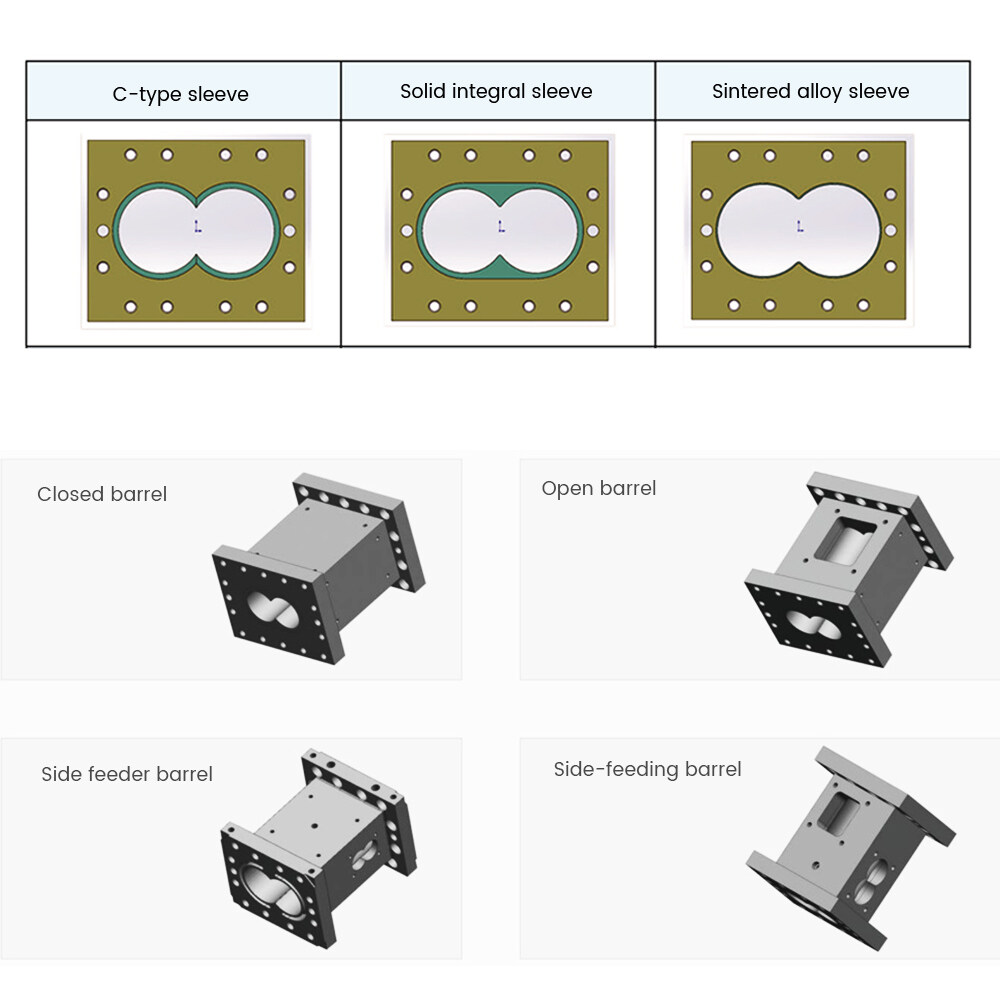

The barrel of our twin-screw extruder is meticulously designed to accommodate the rigorous demands of modern extrusion processes. Fabricated from premium-grade, wear-resistant materials, it ensures optimal performance under continuous operational stress. The internal lining is treated for enhanced corrosion resistance and durability, suitable for processing a wide range of thermoplastic materials. Precision-engineered temperature control zones allow for precise thermal management, critical for maintaining the integrity of heat-sensitive compounds. This barrel is compatible with various modular screw designs, facilitating easy adaptation to different extrusion tasks, from compounding and blending to masterbatching and recycling. Enhanced with features for streamlined maintenance and cleaning, it significantly reduces downtime and boosts production efficiency.

C Sleeve Barrel:

38CrMoAla Nitrided Steel Barrel:

HarC Alloy Barrel:

316L Stainless Steel Barrel:

Cr26 and Cr12MoV Solid Sleeve Barrel:

Powdered Nickel-Based Alloy Solid Sleeve Barrel:

Imported Powder Metallurgy Solid Sleeve Barrel:

Imported Powder Alloy HIP Formed Sleeve:

Nickel-Based Alloy Solid Sleeve (HIP Forming Process):