Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Unveiling the Top 7 Comparative Properties of Engineering Plastics

Engineering plastics refer to a class of high-performance polymer materials that can be used as structural materials, withstand mechanical stress over a wide temperature range, and be used in harsh chemical and physical environments.

Engineering plastics are widely used in industries such as electronics, automotive, construction, office equipment, machinery, aerospace, etc. With the advancement of material technology and design processes, the application of engineering plastics as substitutes for metal materials is increasing. Substituting plastics for steel and wood has become an international trend.

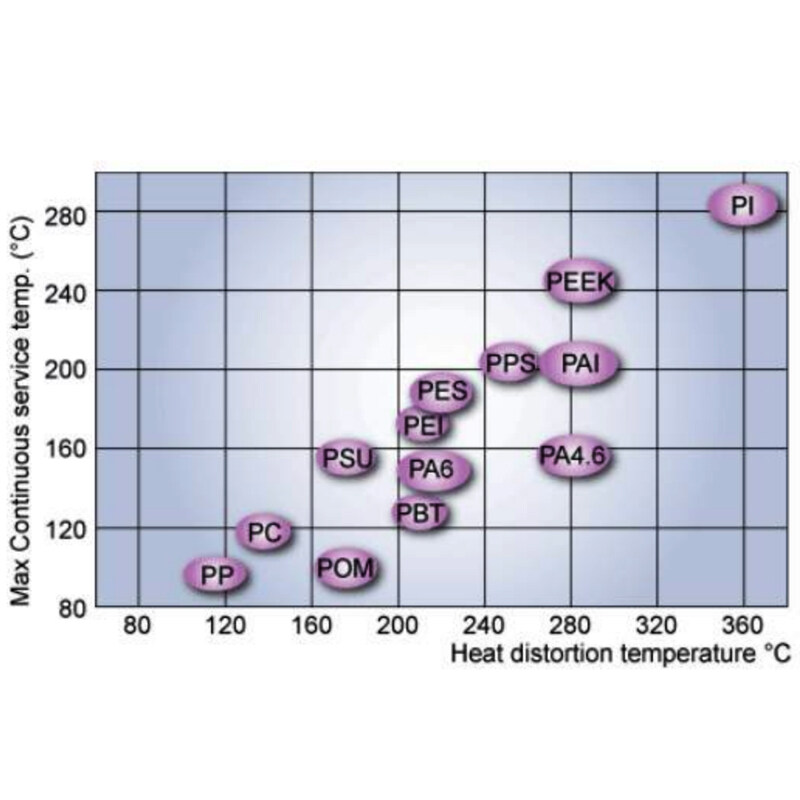

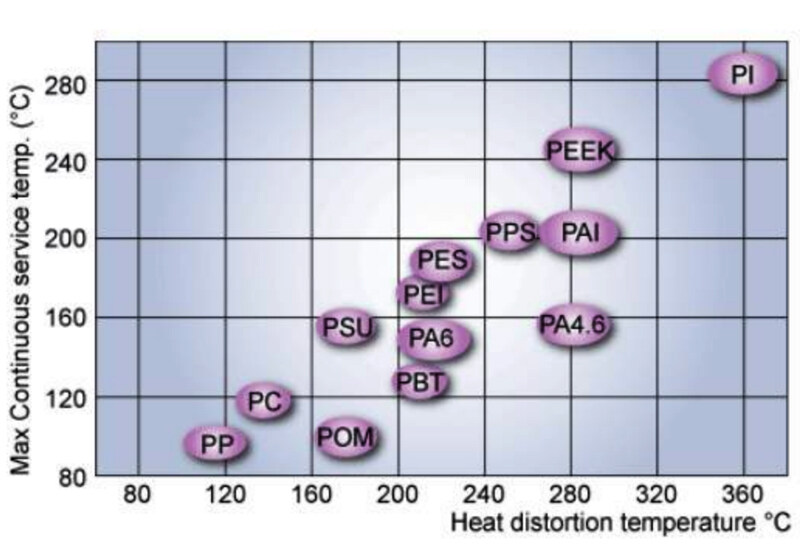

1. Heat Resistance

One key factor to consider when choosing a material is its heat resistance. Generally, increasing the maximum operating temperature of a material requires a corresponding increase in cost. The addition of fillers can greatly increase the hardness and heat deformation temperature of the material. Moreover, for high-performance and specialty polymers, the addition of glass fibers can significantly reduce costs. Therefore, the use of glass fiber-filled polymers as substitutes for metals is common.

Adding carbon fibers to high-performance materials can greatly increase their hardness and heat deformation temperature. Compared to glass fiber filling, filling with carbon fibers has the following advantages:

- Higher hardness

- Lower density

- Good conductivity

- Good friction performance

For these reasons, carbon fibers are often used in automotive fuel delivery lines and fuel systems.

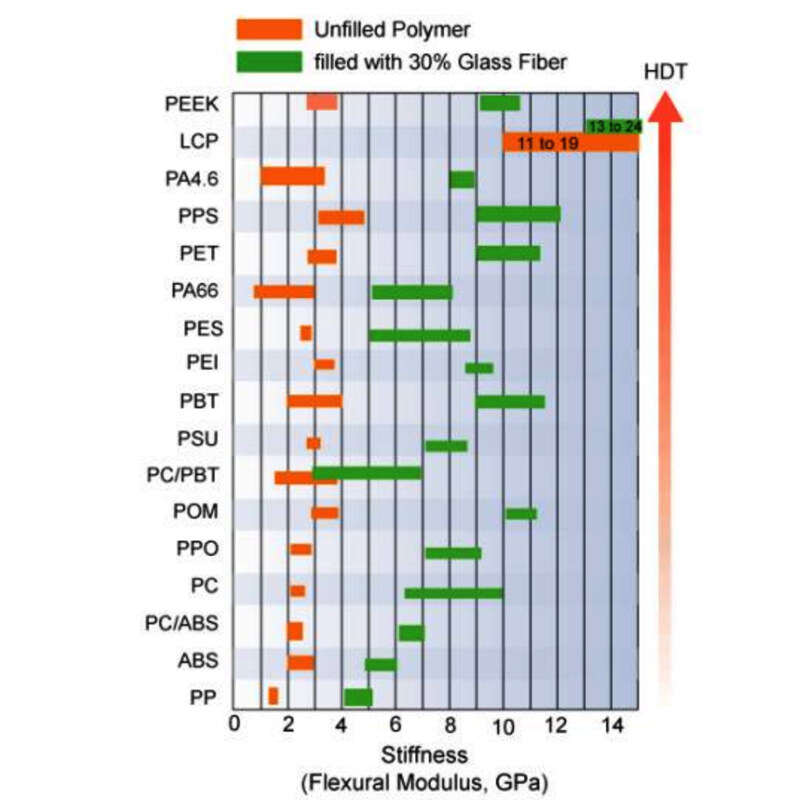

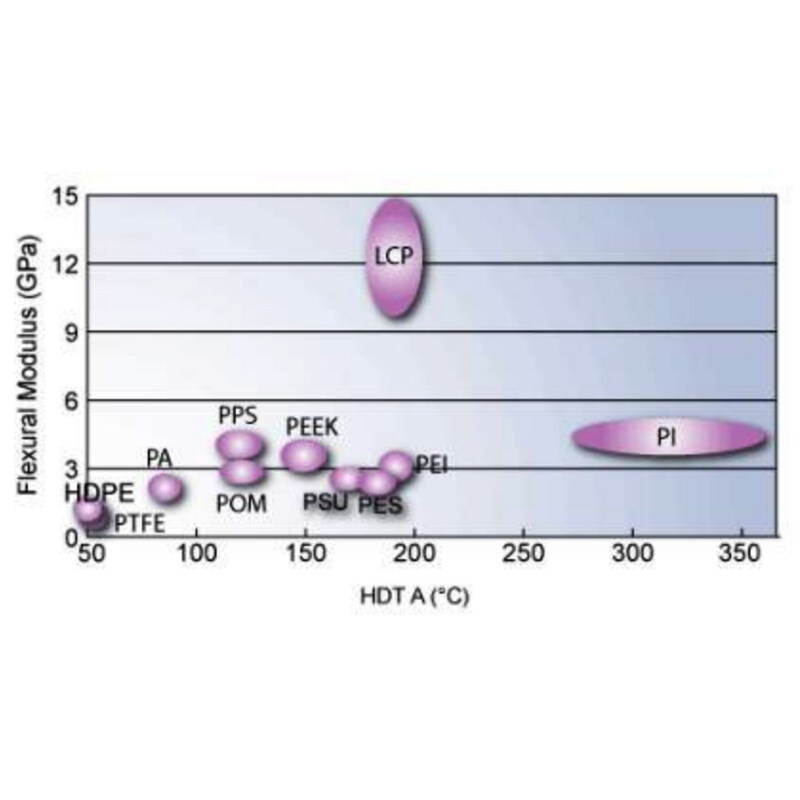

2. Hardness

One of the biggest advantages of metals compared to plastics is their high hardness (on average, about 8 times higher than plastics). However, in many practical applications, such high hardness is not necessary, and it can be supplemented by flexible design, skeleton reinforcement, and low density. In many cases, hardness is also a key performance factor.

Effects of Fillers and Fibers:

The addition of fillers and fibers can greatly increase the hardness of materials. When surface appearance is not a major concern, glass fibers are often used due to their high cost-effectiveness. However, glass fibers can cause material anisotropy, reducing its processing performance and increasing wear.

When appearance is important, mineral fillers such as calcium carbonate, talc, wollastonite, and mica are good choices. However, the hardness and heat deformation temperature of materials filled with mineral fillers are much lower than those filled with glass fibers.

For higher-grade products, carbon fibers can be used as fillers to give materials very high hardness.

Other advantages of filling with carbon fibers include:

- Conductivity

- Excellent friction performance

- Low density

3. Impact Resistance

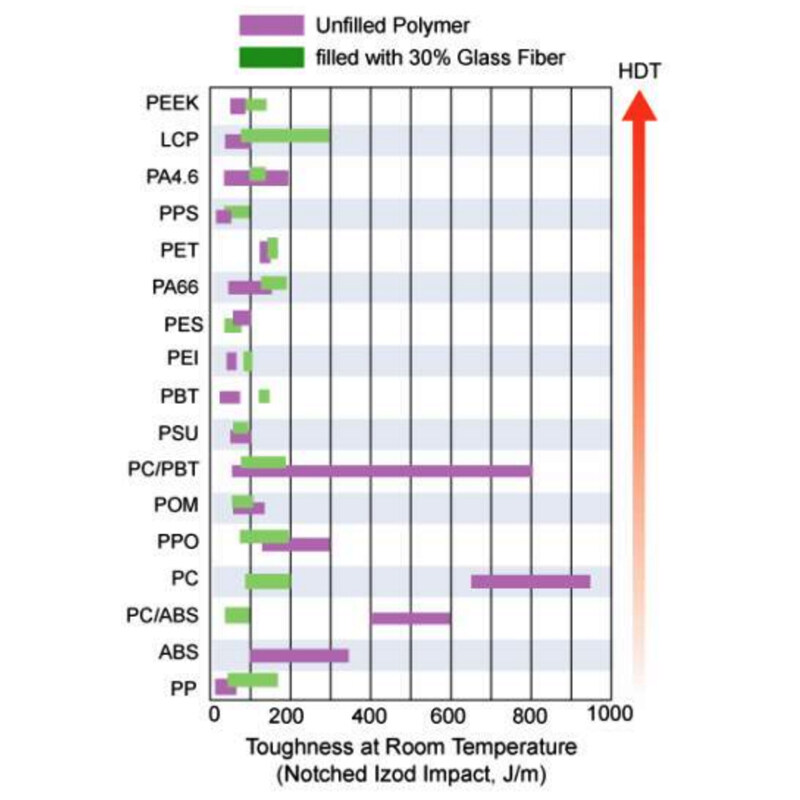

In many practical applications, impact resistance is a key performance factor. Polycarbonate PC and its blends, such as PC/ABS resin and PC/PBT resin, have high impact resistance at room temperature. These materials are excellent choices for continuous operating temperatures below 100-120°C. Materials filled with glass fibers have higher hardness, and liquid crystal polymers LCPs exhibit outstanding performance.

Impact Performance Modifier Effects:

The addition of impact performance modifiers can greatly enhance the toughness of many brittle polymer materials. The toughness of polymers is determined by the polymer itself, the amount of impact modifier, and the quality of dispersion of the modifier in the matrix. However, in all cases, you must compromise between toughness, hardness, chemical resistance, and processing performance.

4. Tear Resistance

Self-lubrication and Wear Resistance:

One promising area for plastics to replace metals is in friction applications, such as gears, pump rotors, engine components, brake components, sliding parts, etc. In this field, plastics have the following advantages:

- Flexibility in design

- Weight reduction

- Self-lubrication without using lubricants

- Noise reduction

Because these urgent applications require materials with low dynamic friction and good wear resistance to avoid heat generation at the contact interface, the following points must be achieved:

- Avoid reduction of mechanical properties

- Minimize material wear

- Avoid smooth phenomena

Very few materials inherently have good self-lubrication and wear resistance. Therefore, these properties of the material itself usually cannot meet industrial requirements. For this reason, friction materials often contain layered fillers, silicone oils, and some polymers. Poly tetrafluoroethylene PTFE is a polymer commonly used in commercial products. In some cases, the choice of final material will also depend on the working temperature, hardness, or chemical resistance.

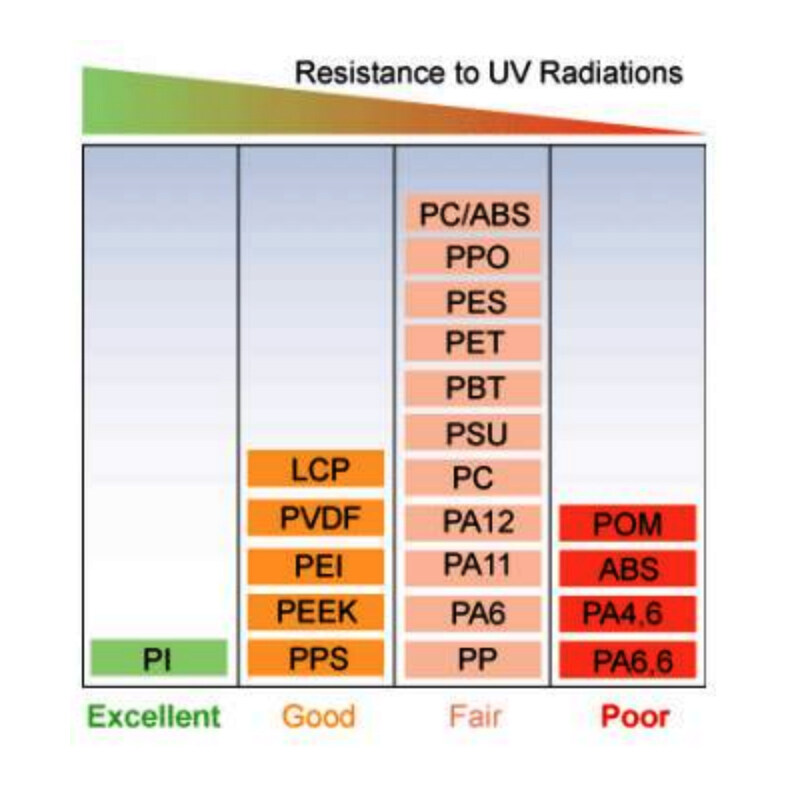

5. Chemical Resistance

In some applications, such as engine parts, pump parts, fuel delivery lines, high-performance pipes and fittings, these materials need to withstand harsh working conditions, resist many chemicals at high temperatures, and maintain their mechanical properties and dimensional stability for a long time.

In many cases, semi-crystalline polymers with high glass transition temperatures (Tg) can provide the best cost-chemical resistance balance. Among these semi-crystalline polymers, fluoropolymers, polyphenylene sulfide PPS, polyether ether ketone PEEK, liquid crystal polymers LCP are excellent choices, especially when good chemical resistance is required at high temperatures. Compared with semi-crystalline polymers, amorphous polymers generally have outstanding chemical resistance, especially to organic solvents, hydrocarbons, and fuels.

Conflict between Chemical Resistance and Impact Modifier:

To meet industrial requirements, many polymers contain impact performance modifiers. In most cases, adding impact modifiers to engineering plastics or high-performance polymers greatly reduces their resistance to fuels, hydrocarbons, and other organic solvents. However