Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

This article provides a detailed analysis of the collaborative operation of metering devices, twin-screw extruders, and downstream systems to help process engineers understand the adjustment principles of each part. This understanding is crucial for controlling final component characteristics and managing the mixing process.

We will discuss aspects such as the feeding system, material viscosity, and downstream processing in detail.

1. Metering System

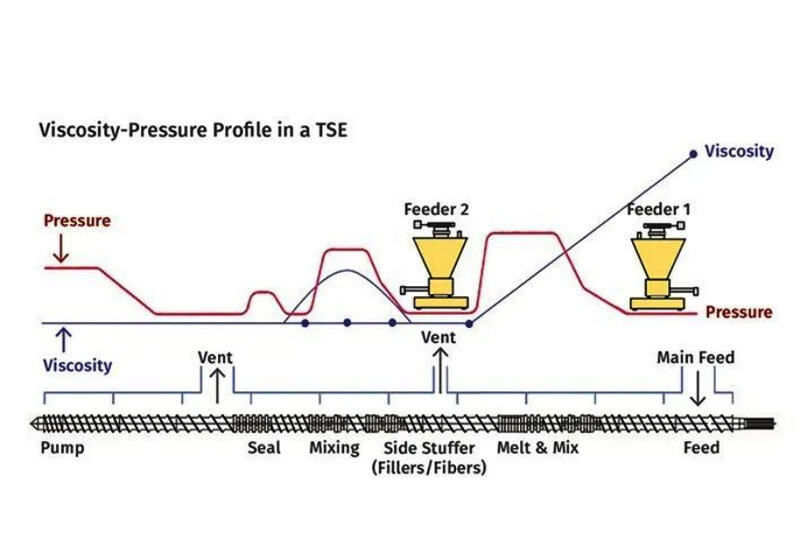

The pre-mixed materials can be metered into the twin-screw extruder using a volumetric feeder. Typically, a Loss-In-Weight (LIW) feed rate is specified to accurately meter individual or multiple material streams into the process section of the twin-screw extruder. The pressure gradient in the process section of the twin-screw extruder is largely determined by the selection of screw elements, allowing the introduction of materials (such as fillers or fibers) downstream through side feeders or liquid pumps.

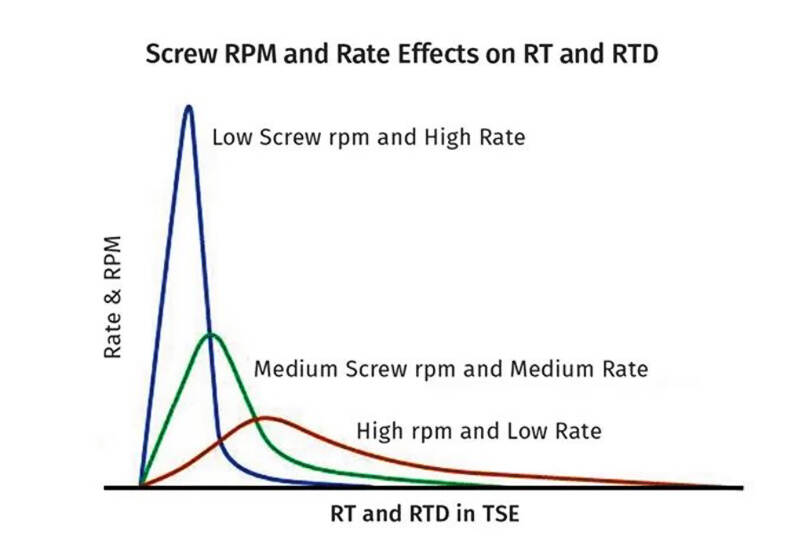

Materials in different forms, such as pellets, powders, fibers, and liquids, can be metered into the twin-screw extruder. If the extruder is starve-fed, the process space between the screws and the barrel is partially filled. In this case, the output rate is set by the feeder because the screw speed is independent and can be coordinated with the feed rate to optimize mixing efficiency. The residence time (RT) in the twin-screw extruder is largely dependent on the feed rate, and the residence time distribution (RTD) is determined by the screw speed. The inherent RTD of the twin-screw extruder mixing system can help "balance" minor feed rate fluctuations.

The relationship between the feed rate and screw speed needs to be combined with screw design and mass transfer/mixing characteristics of the adjustment process. Understanding the five inherent regions in any twin-screw extruder is insightful due to the intricate relationship between the feed rate, screw speed, and mixing:

Changing the screw speed (at constant rate) significantly affects the RTD and "mixing experience." Increasing the screw speed widens the RTD, while decreasing it makes it narrower.

2. Viscosity

Viscosity also plays a role in shear stress/mixing in co-rotating twin-screw extruders affecting dispersion mixing efficiency.

The calculation is as follows: Shear Stress = Peak Shear Rate × Viscosity

Higher viscosity increases shear stress and thus enhances dispersion mixing efficiency. Viscosity (and shear stress) is at its maximum in the early stages of the melting process in the twin-screw extruder, aiding dispersion mixing. In the later stages of the twin-screw extrusion process, viscosity decreases with relatively low shear stress.

The twin-screw barrel is modular and utilizes internal bores for cooling. Each barrel section, typically L/D=4, utilizes PID temperature controllers to set temperature setpoints. Temperature profiles, combined with screw design, are used to strategically manage melt viscosity (shear stress) and the "mixing experience."

For example, a higher temperature setpoint in the melting zone may soften the resin and reduce dispersion mixing at the front end of the process section. Introducing materials downstream after melting (and reducing viscosity) can avoid unnecessary wear and degradation of shear-sensitive materials. Manipulating cooling, combined with screw design, is a useful tool to achieve the desired mixing effects.

Note that smaller co-rotating twin-screw extruders demonstrate a significantly more pronounced ability to control temperature and viscosity. In smaller co-rotating twin-screw extruders, the ratio of heat transfer surface area to material volume is larger, resulting in higher efficiency. This is why most extrusion processes do not scale by volume.

3. Examples of Co-Rotating Twin-Screw Extruder Systems

Premix: Formulation premix can be prepared in batch mixers and then metered into the twin-screw extruder. To determine the acceptability of the premix, a small batch can be mixed and shaken in a glass jar; if no separation occurs after shaking, the premix is acceptable. Using powdered resin helps minimize segregation effects in the hopper.

Premix should now also be seen as part of the "mixing process." Premixes typically achieve higher twin-screw extruder throughput; careful design of the melting zone to avoid compaction/caking effects, and high shear stress in the melting zone are particularly advantageous for dispersion mixing. Examples of products benefiting from premix systems include masterbatches, flexible PVC formulations, and alloys/blends. Small samples are ideal for configuring a premix twin-screw extruder.

Multi-Feed: The feed flow can be metered into the twin-screw extruder feed port using a LIW feeder. Granules and additives are usually metered into the main feed port and/or various downstream positions. Depending on batch size and formulation, some premix may still be necessary.

Sometimes, the compaction phenomenon of additive granules during the melting process can produce agglomerates that are difficult to disperse later in the process, so it is best to meter them into the melt and manage the residence time and "mixing process" of different feed flows. The inherent pressure gradient in the starve-fed twin-screw extruder allows for the introduction of materials downstream after the melting step.

Side Feeder is a device commonly integrated with twin-screw extruders to introduce fillers, fibers, and other materials after plasticization. Like the twin-screw extruder, the side feeder uses a twin-screw helix to "push" the material into the process section of the twin-screw extruder, avoiding the high shear melting zone. This is why side feeding is currently popular, to minimize glass fiber wear and avoid processing shear-sensitive fillers such as flame retardants or chemical foaming agents.

Injection of various liquids is also common, including environmental injection and heating injection. Reactive extrusion processes (i.e., used for thermoplastic polyurethanes) are often carried out on twin-screw extruder systems.

Tandem Systems: Tandem systems string together a series of unit operations to continuously modify, mix, and devolatilize polymer formulations. The length-to-diameter ratio of co-rotating, inter